The Construction

The house is of an extremely high degree of difficulty from a pure completion point of view. It has been a tremendous challenge to find materials that could be used to create the many bows and unique features in the different radiuses. Many times, ideas were tested, only to decide a whole different solution. But common to all decisions regarding this construction no corners have been skipped.

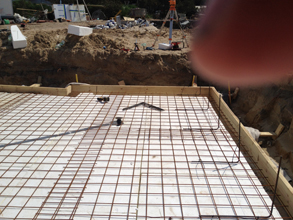

The construction is made in an iron structure rolled in galvanized steel seen in the pictures below. Afterwards, mounted feet into the rolled steel on the outside have been made to lock the assemblage. Thus, it has been possible to get the large interior space, which is not directly supported. On the contrary the pressure from the roof goes against the arch and down into the outer wall where 2 strong steel legs are positioned in support of the structure. The iron construction of the house is so advanced that only one company bid for tender on the job, although five were contacted.

Besides, galvanized steel wood is used abundantly to build walls. For all curved walls there are provided top and bottom straps, which are cut out with a compass saw at their given radiuses. Several compass saws and blades were worn out for this task as almost everything takes round shapes and is very special. Interior walls are in Fermacell, exterior walls are in STO Ventec plates. Where the radius is below approximately 3 meters STO Ventec plates are used, both inside and outside, as they can be bent almost infinite. There is glass fiber fabric on both sides of the plate accordingly, it does not break.

When the floor of the house was casted, curvatures were beaten in the floor out from the center (master bedroom). Small marble tiles of 10 x 10 centimeters were subsequently added. This means that the closer you get the master bedroom, the more tiles lye in a bow. This gives an amazing effect in the house.

The kitchen is completed with all possible facilities. And on all tables there has a covering of granite. The large kitchen island in the middle has additionally a small bar in one corner, and it has a giant granite plate on top of it. The granite plate weighs 480 kilograms and it is carved conically with a radius made according to the building's center.

The pool is an overflow pool where the water constantly runs over and there is a dripping sound in the pool area at all times. The pool is made of beautiful crystal blue glass mosaic. The pool is on the whole 30 cubic meters. The pool is water proofed from the outside, with a special water proof cover of clay, since the area in Blåvand is troubled with serious problems with invasive groundwater. The pool is casted in aggressive concrete and the corners are secured with fiberglass. There is a wet room system to comply with the BR10, which may be considered unnecessary though. Then glass mosaic is laid glued with epoxy sealant and after-grouted with the same Epoxy Grout. Hence all precautions are taken to be on the safe side in terms of water resistance, both from the outside and the inside.

The steam bath is also made of pure glass mosaic with seat heating, shower, lights in the seats, starry skies, music and an aroma fragrance system. The seats in the steam cabins are conical and curved to match the building's center. It gives a nice effect in the glass mosaic steam room because they are curved. The seats are made in a creative mixture of porous concrete and 200 millimeters sewer pipes. There is central heating in the seats and the backrests in order to make them feel warm to sit on. It is an important detail because a steam room with cold seats appears to be useless. The joints of the glass mosaic is self-glowing epoxy grout. And it is all lit with 12 spots in the seats and 250 pieces of sparkling stars in the ceiling.

The spa-platform is the house's final touch. The back wall, which the platform is fixed on, is a 350 fundaments block wall casted in 'aggressive' concrete. There are strengthened crisscross with 14 millimeter armed steel. A steel construction is provided which is galvanized after construction. The iron construction is then bolted to the wall with 24 through going 16 millimeter bolts. In the roof over the pool area, two heavy iron bars are laid. At the end of the spa-platform, 2 welded pieces massive steel tubes with a diameter of 25 millimeters are welded, which then is welded to the 2 large iron bars in the roof. Each bar will withstand a pull of approximately 15 tons. The two tubes are hard to spot, because there are railings around them. The 2 bars are essential for the spa-platform to stay where it is. The iron structure has no connection to the rest of the roof, so any snow loads will not affect the spa-platform’s location.

The ceiling is a real show stopper in this project. The ceiling is made of 19 millimeter formwork boards. Half of the panels are broken in 5 pieces so as to be approximately 19 x 19 millimeters. The other half splits into 3 pieces leaving approximately 30 x 19 millimeters. The major pieces are then painted with white profile lye. The small pieces are stained in black and consequently they break up after each other in disguise. To be exact, first a white row then a black row are painted. I have used approximately 15 kilometers of lists including wasted materials to create this ceiling. This is without any doubt whatsoever the house's most demanding job. Additionally, there are drilled and countersunk 350 LED spots into the ceiling.

Genvex installations are irreplaceable to this house. There are 2 installations in the house. The large installations dehumidify the pool area, the kitchen area and the fitness room area. On both sides to the pool area (kitchen & Fitness) an over-pressure is constructed by placing one air supply valve more in the room than the exhaustion valve. This enables the heat, humidity and chlorine vapor from the pool and the spa to stay in the wellness area. Hence, there is absolutely no chlorine smell in this house elsewhere, than where it is to be. The second slightly smaller installations service the bedrooms.

Electronics are based on the most recent options. There is a multi-room music system from the American Russound. It is a channel system accessible in the kitchen, living room, wellness room, fitness room, master bedroom, sauna, steam-bath room and outdoor on the porch. The System is constructed using LAN cables and ordinary loudspeaker cable. In all accessible rooms Russound has touch panels. Of the audio-sources there are FM radio, PC, IPhone Apple AirPlay, Bluetooth, Netradio and Spotify via PC and Smart TV. It makes it possible to listen to almost all music in all accessible rooms. And with Bluetooth and Apple AirPlay, it is almost possible to connect all external units to the system.

All rooms have Samsung Smart TV which is connected to the Internet. There is a 24 hour non-stop entertainment from for example Netflix and Spotify, so there are plenty of opportunities to spice up your day with entertainment from the 8 Smart TV systems.

Suppliers to the Project.

Idea and drawing work is done by DNA Architects in Varde. DNA Arkitekter DNA has also been invaluable in providing advice and ideas, when this was required.

Steel construction, winding staircase, small loft ladders are made of BH Montage in Vejen.

Windows and insulated glazing are supplied by Wellvex A/S windows and doors.

Roof is made of Dansk Tagteknik A/S

Interior glass walls is supplied by Triplan Glas and Facade

All raw material are supplied by Davidsen Tømmerhandel A/S Davidsen department in Odense was also responsible for contacts with other sub-suppliers

Granite and table plates are supplied by E-byggeri who made templates and who made the 35 granite plates in the house.

Genvex installations are supplied and arranged by Sundthus who also supervised the pipe construction in the advanced roof construction.

Plumbing and heating-pumps are installed by Hansen og Dahl from Vejen.

Digging, sewer and landscaping is established by Jessen Entreprenørforretning i Blåvand. (It was the first time he dug a round base)